3

May2024

How to secure project schedule “buy-in”.

To effectively engage a resistant superintendent, foreman, or other team member when trying to build a project schedule is a feat not to be taken lightly. So often, I have heard people say “What’s the point it’s going to change anyway” or “You can’t plan for everything that’s just too much”. Many people in the construction field think the project schedule is just a colorful piece of paper, never realizing the powerful tool they have available to them if they would just be willing to use it.

Schedules are a living document that changes with field conditions and job progress. Not every task can or should be scheduled, however, if there is enough detail, good project standards utilized, and sound logic then every project will finish on time and almost always within budget. I have always said, ” If a project is having schedule issues, then it is also having budget issues.”

Where to Start

Finding a balance between assertiveness and patience will be the key to determining your success as a project scheduler or manager. As a project scheduler/manager, it is your job to guide the project team towards recognizing the value of planning and execution. So, how do you do that?

Leveraging scheduling software like Primavera P6 or OPC is merely a technical aspect of project management and scheduling. True mastery lies in cultivating team buy-in and fostering cooperation around the schedule. This demands a blend of communication skills, empathy, and strategic thinking.

Buy-in Strategies

One strategy I like to call “ leading from the back” or “ pushing from behind” is to subtly influence the project team by letting them believe they are driving the entire planning process. To pull off this technique you must have a good grasp of the project specifics and potential challenges. It requires you as the leader to educate yourself before approaching the team. Patiently collaborating with them, you can gradually introduce alternative perspectives & possible scenarios. Carefully crafted questions designed to elicit a response that must contain more than a yes or no response is the main ingredient in this strategy.

Staying genuinely curious is a great way to build open dialogue and usually sparks interest from the other stakeholders. This process provides an atmosphere conducive to collaboration and getting minds to shift into planning modes without realizing it. This is a more “passive” way to build a project schedule and hopefully, when all is said and done, the team members will realize the benefits of a well-structured plan instead of reacting to the moment.

A “seeing is believing” strategy to try to gain converts is to utilize what-if scenarios. Being able to see the impact on the completion dates of potential directions taken can be a powerful tool in gaining trust and commitment to the process. For instance, integrating utility mapping services can provide crucial data that visualizes potential challenges and timelines more effectively. Engaging Topographical Surveyors early in the project can further enhance this strategy by offering precise measurements and insights that inform critical planning decisions. Additionally, considering sustainable options, such as installing office solar panels, can showcase a commitment to energy efficiency, influencing buy-in from stakeholders through visible environmental responsibility.

Another strategy I like to call “ full transparency” is taking the time to explain the rationale behind scheduling decisions or the logic behind each task. This fosters a culture of collaboration and mutual understanding. This is also a great teaching tool for project team members who may be new to the process of construction and schedule building. Furthermore, actively seeking input from the project team on process, resource allocation, and logistics ensures that an accurate schedule has been complied. Discussing and reviewing all of the logic and work activities as a group strengthens team cohesion, builds confidence in the project schedule, and cements/records the agreements made to maintain the project schedule. In addition, utilizing innovative solutions like those offered by https://thermalbreakwindows.co.uk/ can further enhance energy efficiency and sustainability in construction projects. When it comes to enhancing workplace productivity and ambiance, the office lightning company offers a wide range of innovative solutions tailored to meet you needs.

Final Thoughts

It’s important to remember whether you are working with a subcontractor, owner, or direct hire tradesmen each conversation offers valuable insights into the nuances of the project and construction processes. By consistently adapting your approach to meet the team’s needs and addressing their concerns, you not only enhance your capabilities but also foster a culture of continuous improvement within the project team. These iterative processes described above build strong reliable schedules and also cultivate a more harmonious and efficient working environment.

Holly Henn is the President & CEO of CBA and you can read more about her in her Bio. CBA offers a wide range of project schedule solutions that you can learn about by attending one of their monthly Primavera P6 training classes. They also offer Scheduling Support, as well as, Project Software and Staffing.

18

Jul2023

OPC Baselines and Time Travel

Before we get into OPC Baselines and Time travel, Oracle Primavera Cloud (OPC) is the newest Project Management solution offered by Oracle. While the OPC Scheduling suite and Primavera P6 are very similar in functionality, OPC has introduced several additional features that will give project managers powerful tools not previously at their disposal. We at CBA, Inc. are really excited about OPC and over the coming months we invite you to join us as we dive into many of the new features that we think make it a solution worth looking at.

For our first blog in the series, I want to discuss one of my favorite features in OPC; OPC Baselines and Time Travel.

That’s right, OPC allows you to travel through time. Ok, maybe not full-on time travel, but a special Baseline feature in OPC allows us to do the next best thing. Before we get into that though, a bit about Baselines in general.

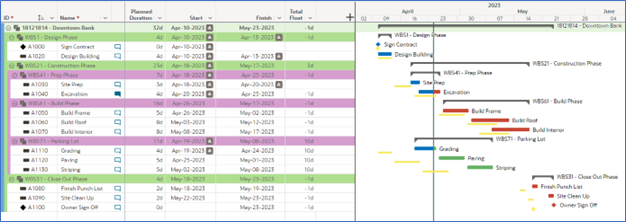

The Baseline is a snapshot of the project as it existed at the time the Baseline was created. Project managers typically create the initial Baseline just before the project starts. This allows them to easily identify where slips have occurred. As the project progresses, project managers will be able to view reports displaying the original plan (the Baseline) and compare it against the current project.

The Baseline is an important tool in any project manager’s arsenal regardless of which scheduling software you are using. The ability to see the variance between what was planned and what actually happened offers powerful reporting options to schedulers as they manage their project. OPC continues to offer similar Baseline functionality as P6 with a few interesting additions.

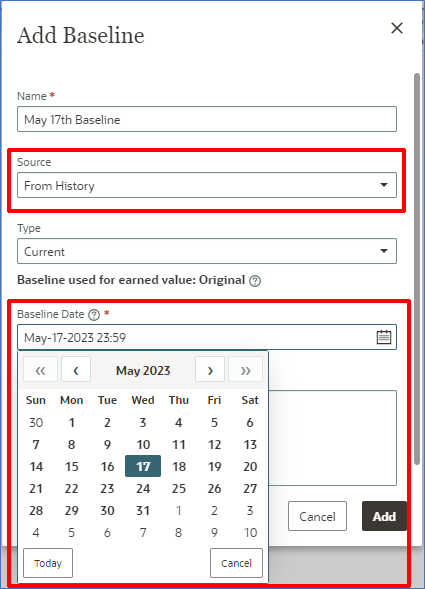

Most Project Management Software suites have similar functionality so many of you are probably familiar with this concept. Where OPC shines (and back to the topic of this blog), is the ability to go back in time and create a Baseline from any specific day in the past.

Essentially, OPC makes a copy of your project every night at 11:59pm. The Baseline “From History” feature allows us to access those “copies” while adding new Baselines. With this new feature, we can create a Baseline for our project based on any date from the current date all the way back to the beginning of the project.

The ability to compare the current project against the project as it existed on any day from the past (on the fly!) is something we never had the power to do before and gives us a level of control over reporting that can help with change orders, claim situations and more.

For instance, events may happen on the job site that at the time you did not realize would be of great significance. Only later do you recognize the impact it had on the project. With this feature, you can now go back in time and create a Baseline just before that event happened. Want to see what the project looked like just before that big storm? No problem! Do we need to see what the project looked like before we shifted the focus from “here” to “there”? No problem! Heck, just plain forgot to make a Baseline at the beginning of the project? No problem!

In summary, OPC offers the same great Baseline features we had in P6 but now combined with the “From History” feature, Project Managers have more power than ever at their disposal for comparison reporting against their projects.

Come learn about this and many more great OPC features in one of our training classes. Click here for more information on dates and locations.

Curtis Callaway is a Sr. Consultant and Instructor with CBA and you can read more about him in his short Bio. He is the lead Instructor for our Atlanta, GA facility. You can register for one of his upcoming OPC class in Atlanta below.

OPC Scheduling – August 1-2: Atlanta, GA

OPC Scheduling – October 17-18: Atlanta, GA

14

Feb2018

Using Fill Down in Primavera P6 – video

This short video shows how to save time scheduling your projects by using the “Fill Down” feature in Primavera P6. Add this shortcut to your routine to become a more effective scheduler. For more information about our instructor led, in-person training courses at CBA check out our Class Schedule.

read more31

Jan2018

The Benefits of BIM

CBA Subject Matter Expert on BIM, Cynthia Stiffler, President of VDC Services for Rock Ridge Virtual Design Construction, describes the different maturity levels of BIM, through the concepts of 4D, 5D and 6D scheduling, which are used to indicate the elements and benefits of increasingly complex BIM models.

There is a wide spectrum of possible uses of BIM on construction projects. At one extreme architects and engineers can use BIM simply to produce better quality design documents without providing the digital model to any other party. Contractors, likewise, can separately create models for estimating, fabricating or simulating construction without sharing the models.

Used in such limited ways, BIM does not come close to realizing its full potential. However, to truly leverage its potential, incorporating topographical surveys can significantly enhance BIM’s capabilities. At the other end of the spectrum, companies like the GPR Survey Company utilize BIM can provide a collaborative framework among all project parties, allowing the free-flow of data about what is being designed and how it will be constructed. Collaborative use of BIM takes full advantage of BIM’s capabilities. For instance, BIM can be instrumental in planning and implementing cladding for commercial properties, allowing for precise modeling and visualization of cladding materials, installation techniques, and their impact on the building’s overall aesthetics and performance. For more information on project management for horse arena construction, you can check out this resources at https://horsemenageconstruction.co.uk/project-management-for-horse-arena-construction/. For instance, scissor lift training providers can integrate BIM into their safety protocols, enhancing communication and coordination during construction activities. Additionally, ensuring the teams are trained through work platform safety courses can further enhance on site safety and operational efficiency.

3D – Model

- Model walkthroughs. These provide a great visualization tool enabling designers and contractors to work together to identify and resolve problems with the help of the model before walking on-site.

- Clash detection. Traditionally design drawings must be coordinated to assure that different building systems do not clash and can actually be constructed in the allowed space. Accordingly, most clashes are identified when the contractor receives the design drawings and everyone is on-site and working. With clashes being detected so late, delay is caused and decisions need to be made very quickly in order to provide a solution. BIM enables potential problems to be identified early in the design phase and resolved before construction begins. Illustrating the advantages of BIM, one project for the General Services Administration in America saw BIM model reviewers find 257 constructability issues and 7,213 conflicts. On the same project, traditional plan reviewers found six constructability issues and one conflict.

- Project visualization. Simple schedule simulation can show the owner what the building will look like as construction progresses. This provides a very useful and successful marketing tool for all those involved in a project. In addition, billboard advertising can be incorporated to further enhance the marketing strategy. For more information on innovative marketing tools like 3D digital billboards, check out this site at https://3dbillboardadvertising.co.uk/what-are-3d-digital-billboards/. Contractors can also use project visualization to understand how the building will come together.

- Virtual mock-up models. Often on large projects the owner will request physical mock-up models so they can visualize, better understand and make decisions about the aesthetics and the functionality of part of the project. BIM modelling enables virtual mock-ups to be made and tested for a fraction of the cost.

- Prefabrication. The level of construction information in a BIM model means that prefabrication can be utilized with greater assurance that prefabricated components will fit once on-site. As a result, more construction work can be performed offsite, cost efficiently, in controlled factory conditions and then efficiently installed. If you’re opening a factory but still want to be eco-friendly, you can click here to get solar panels for factory.

4D – Time

- Construction planning and management. BIM models provide a means of verifying site logistics and yard operations by including tools to visually depict the space utilization of the job site throughout a project’s construction. The model can include temporary components such as cranes, heavy equipment, and fencing. Traffic access routes for heavy equipment, cranes, lifts, and other large items can also be incorporated into the model as part of the logistics plan. Tools can further be used to enhance the planning and monitoring of health and safety precautions needed on-site as the project progresses. For optimal site management, consider including options for construction lift hire in the logistics plan.

- Schedule visualization. By watching the schedule visualization, project members will be able to make sound decisions based upon multiple sources of accurate real-time information. Within the BIM model a chart can be used to show the critical path and visually show the dependency of some sequences on others. As the design is changed, advanced BIM models will be able to automatically identify those changes that will affect the critical path and indicate what there corresponding impact will be on the overall delivery of the project.

5D – Cost

- Quantity Takeoffs. To determine a project’s construction cost and requirements, contractors traditionally perform material ‘take-offs’ manually, a process fraught with the potential for error. With BIM, the model includes information that allows a contractor to accurately and rapidly generate an array of essential estimating information, such as materials quantities and costs, size and area estimates, and productivity projections. As changes are made, estimating information automatically adjusts, allowing greater contractor productivity.

- ‘Real Time’ cost estimating. In a BIM model cost data can be added to each object enabling the model to automatically calculate a rough estimate of material costs. This provides a valuable tool for designers, enabling them to conduct value engineering. However, it should be noted that overall project pricing would still require the expertise of a cost estimator.

6D – Facilities Management

- Lifecycle management. Where a model is created by the designer and updated throughout the construction phase, it will have the capacity to become an ‘as built’ model, which also can be turned over to the owner. The model will be able to contain all of the specifications, operation and maintenance (O&M) manuals and warranty information, useful for future maintenance. This eliminates the problems that can currently be experienced if the O&M manual has been misplaced or is kept at a remote location.

- Data Capture. Sensors can feed back and record data relevant to the operation phase of a building, enabling BIM to be used to model and evaluate energy efficiency, monitor a building’s life cycle costs and optimize its cost efficiency. It also enables the owner to evaluate the cost-effectiveness of any proposed upgrades.

For more information about 4D Scheduling or BIM, contact CBA at 419-874-0800 or by email.

read more21

Feb2014

An Ounce of Prevention is Worth More Than a Box of Donuts

In a perfect world, when awarded a project, you’d be allotted a full week of gloating, “Hoo-hahs!” and chest bumps followed by a full 30 days to submit a preliminary 90 day baseline schedule and another 60 days to submit the complete construction schedule for the full project. Of course, you’d not only have the non-partisan support and participation of the Owner for feedback along the way, you’d also have all your subs identified and ready to go. They’d all come filing into the first weekly project meeting with a fully detailed Primavera project schedule, smiles and a box of donuts to share!

Unfortunately, that’s not the world we live in. In most instances, notification of the award signifies “Go time!” Immediately all parties involved begin the frenzy to get the ball rolling. It seems that everyone from the owner, to the Project Manager, to the subs (if even known) is frantically moving at warp speed to get the project off the ground. While the effort is admirable, it is not always effective. Everyone is working in their own silo and there is often not enough team collaboration from the beginning, especially as it relates to the project schedule.

Even if you have the luxury of 60 days to submit the final construction schedule for baseline approval, the real work on the schedule often begins far too late into that time frame. Everyone is not working together to plan the work accurately, to reflect the real world, intended progression of the project. The Owner will nit-pick about adherence to the schedule specs, the subs will complain that they don’t need a schedule because they have been doing this for years, and the Project Manager will want to strangle them all because he just wants to make things happen, get home in time for dinner at least once this month, and not get sued down the road!

It’s exactly at this time, at the inception of a project, that Critical Business Analysis, Inc. should be brought on board.

CBA is often utilized as a third party schedule consultant to not only develop the project schedule, but to act as an objective team participant to facilitate the collaboration process among all parties involved. We know scheduling and project management. We understand scheduling specs and best practices. We have no private agenda and our advice can be trusted.

Far too often, we are brought into a project only after major issues with the project schedule have been identified. Certainly we can help in these situations, but issues like these, and the meetings surrounding them, are adversarial, ugly and definitely confection deprived.

Whether you are the Owner or the General Contractor, save yourself the agony. Contact us at the beginning of your project to be a “second set of eyes” for the development of your project schedule and then use us as a reliable resource throughout the life of the project to be sure your scheduling effort is still on track. We all know that the project schedule can be your best friend, or your worst enemy. Bring us aboard and let us make the introduction to your new BFF…we’ll even bring the donuts!

read more24

Sep2013

Better P6 Float Management through Proactive Analysis

…if the Finish Date Variance is trending in a negative path, the activity may soon have negative float.

As many times as I have conducted Primavera P6 training, I am always surprised by the under use of one of the basic P6 tools.

A Scheduler painstakingly builds a schedule to reflect reality and then after the project starts, neglects to take advantage of the opportunity to be proactive in managing negative float and variance trends. The tool is the P6 Baseline. Sure, most Schedulers create a baseline at the onset of a project and, if following best practices, assign it to the Project Baseline to make it globally available for all users to view. Assigning to the Project Baseline ensures that any P6 User comparing the “BL Columns and Gantt Bars” is viewing data from the original Baseline.

But how about Updated Baselines for trend analysis?

With all the focus on managing negative float within a schedule, the Finish Date variance trends sometimes get lost in the shuffle. It is extremely important to understand that, even when an activity has positive float, if the Finish Date Variance is trending in a negative path, the activity may soon have negative float. The ability to see the negative trend and adjustment the schedule accordingly can prevent the activity from ever having negative float.

Consider the following:

Utilizing data in the table below, at what point would you recognize that the Foundation activity had a negative float issue? CYCLE 5??

| Update # | Update Date | Activity | Float | BL1 Finish Date Variance |

|---|---|---|---|---|

| Cycle 1 | 6/15/2013 | Foundation | 12 | 0 |

| Cycle 2 | 6/30/2013 | Foundation | 9 | -3 |

| Cycle 3 | 7/15/2013 | Foundation | 5 | -4 |

| Cycle 4 | 7/30/2013 | Foundation | 1 | -4 |

| Cycle 5 | 8/15/2013 | Foundation | -2 | -3 |

If you were capturing updated baselines each cycle and monitoring the negative Finish Date Variance trends, it is likely that you noticed a potential problem on Cycle 3. Being the proactive person you are, you take action to mitigate the negative trend activity from ever getting into negative float territory.

lySo what is the suggested best practice?

- Capture a baseline each time you update the schedule and assign it to the Primary Baseline

- Use variance analysis layouts to monitor trends using Activity Table columns such as BL1 Finish Date and BL1 Project Finish Date Variance.

- Consider capturing past period Finish Date Variances in User Defined Fields to watch for trends occurring over multiple Update cycles.

- Design P6 Report Writer reports to use color coded conditionally formatted cells to highlight negative float/negative finish date trends as red and positive float/negative finish date trends as yellow.

- Take action on the scenario where positive float activities have multiple Update Cycles with negative Finish Date Variances.

18

Nov2011

P6 Expense Dump and Filter

Dumping Expenses to Excel and Filtering by year.

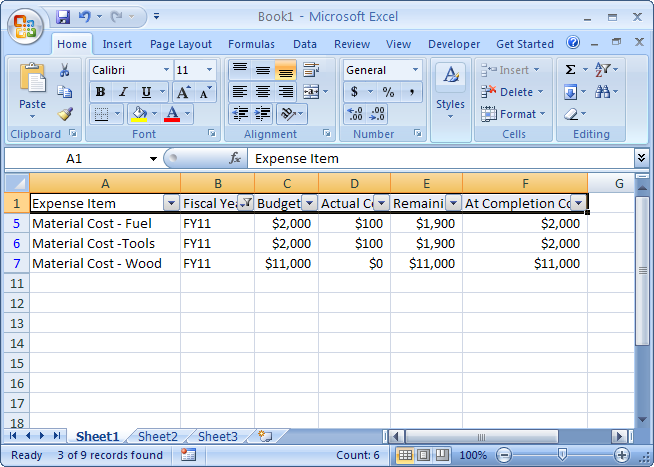

Being able to manipulate P6 data in Excel can sometimes be helpful. Here is a case where I copied expenses from Primavera P6 and pasted them into Excel to filter out a certain year’s data.

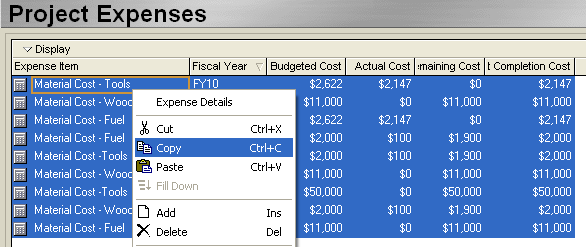

1. In the Expense view, type Ctrl A to select all

a. Right click and choose Copy

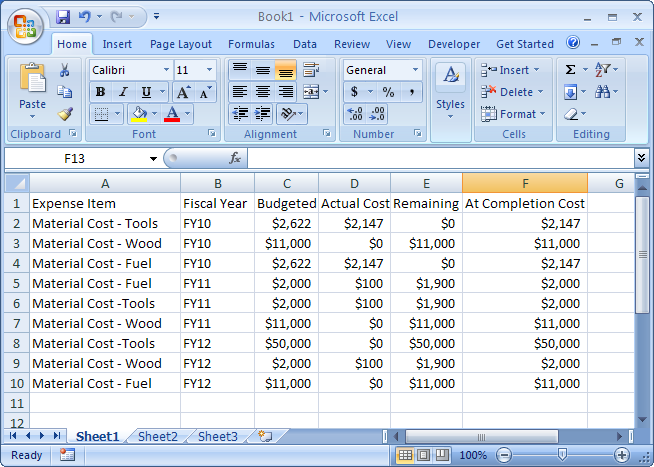

2. In Excel, right click and choose Paste

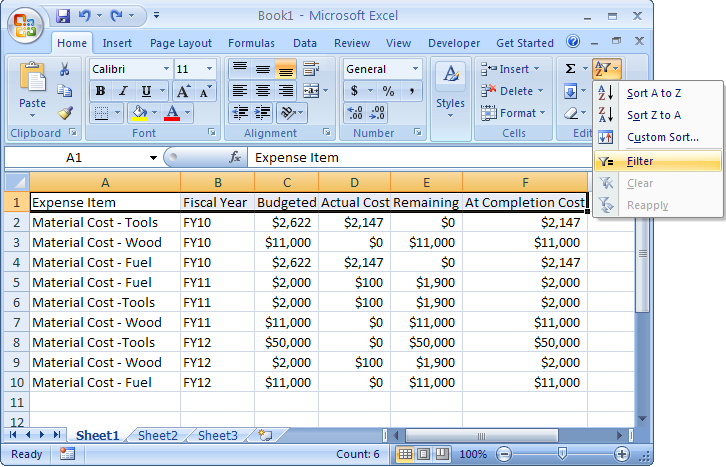

3. Select the top row containing the column titles, Row 1

a. Select the AZ funnel icon, then Filter

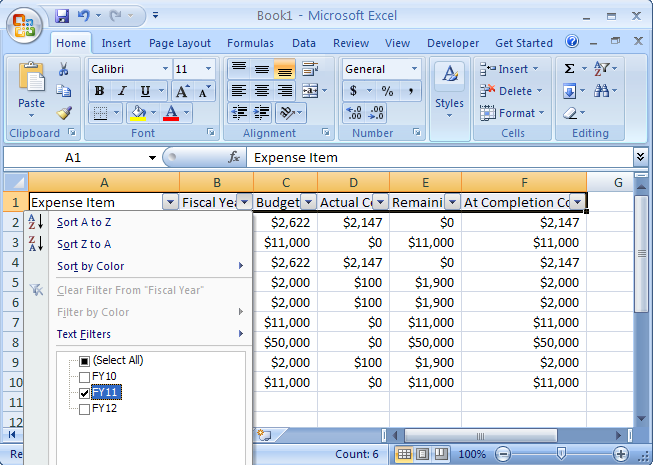

4. Select the Fiscal Year drop down arrow and select the year you would like to see data on:

5. Now data from only 2011 is selected:

read more